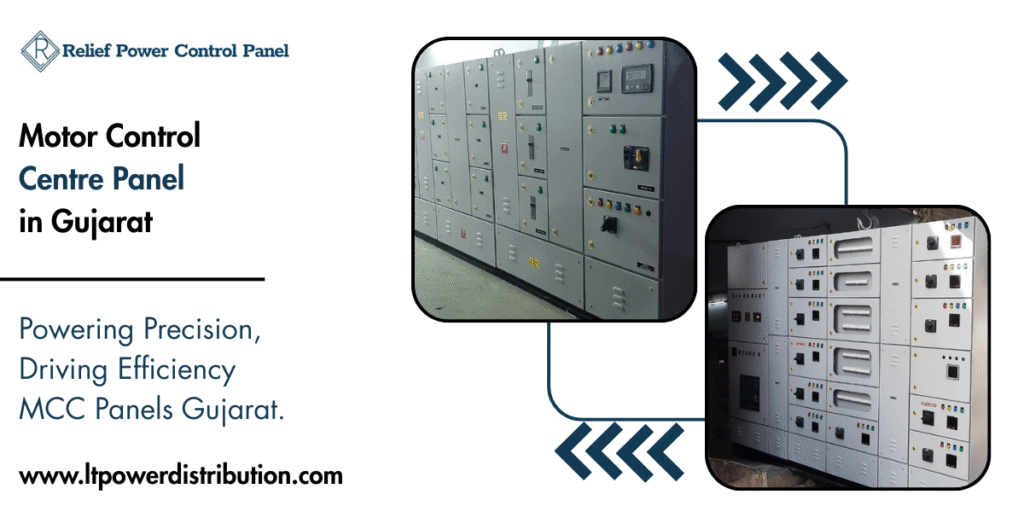

Motor Control Centre Panel in Gujarat

Introduction

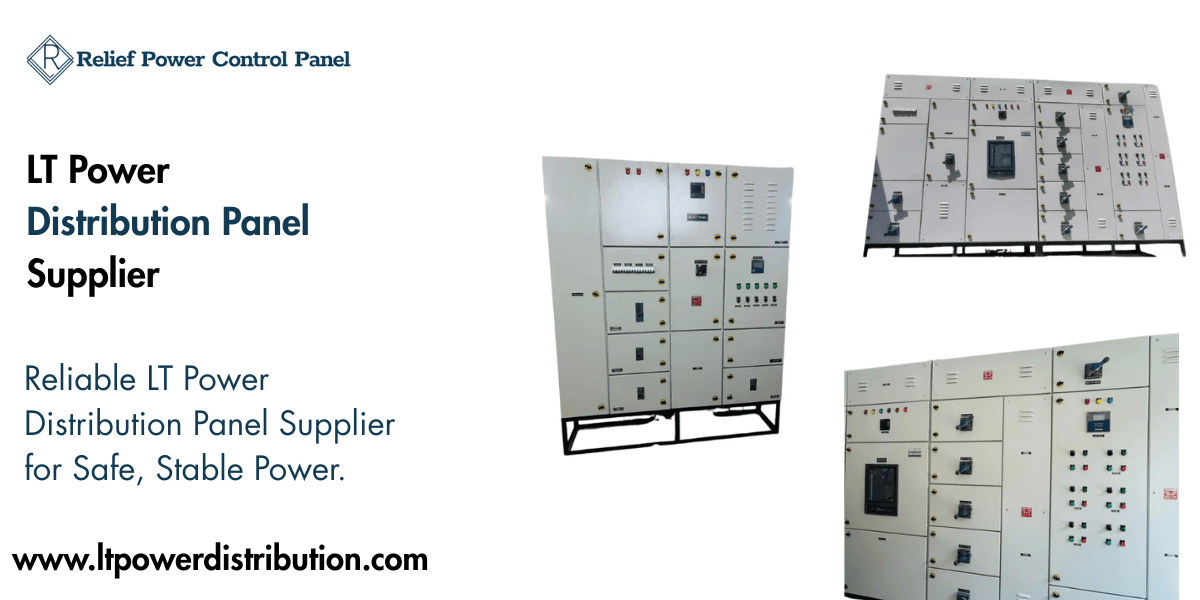

Founded in 2023 in Ahmedabad, Gujarat, Relief Power Control Panel has emerged as a trusted provider of advanced electrical control solutions. As a manufacturer, supplier, and service provider, the company specialises in high-performance systems, including power distribution panels, MCB panels, three-phase control panels, APFC panels, and VFD panels. Each product is engineered using industry-approved designs and premium-grade materials to ensure maximum safety, efficiency, and long-term reliability. Backed by a skilled team and a commitment to innovation, Relief Power Control Panel continues to establish itself as a dependable partner for power management solutions across diverse industries.

Operational efficiency and safety are more than simply objectives in Gujarat’s enormous industrial landscape, where factories, textile mills, and chemical processing facilities serve as the foundation of the country’s economy. The Motor Control Centre (MCC) Panel is a vital component of the electrical infrastructure that is at the centre of many of these industrial processes. These centralised assemblies serve as the brain centres for controlling electric motors, guaranteeing the smooth and dependable operation of everything from large conveyor belts to precision pumps. Developing strong MCC solutions is essential for businesses like Relief Power Control Panel in Ahmedabad to support Gujarat’s industrial development. We are the best Motor Control Centre Panel Manufacturer

Understanding Motor Control Centre Panels

An assemblage of one or more enclosed sections used to monitor, manage, and safeguard electric motors in industrial settings is called a Motor Management Centre (MCC) Panel. These panels allow for the centralised control of several motors from a single location by housing motor starters, protective devices, and control circuits. In sectors like manufacturing, water treatment, electricity generation, and chemical plants, MCC panels are essential. They guarantee that motors run effectively, are protected from malfunctions, and may be managed locally or remotely as needed. We are the best Motor Control Centre Panel Supplier in Ahmedabad.

Why Choose Relief Power Control Panel

- Quality Commitment and Technical Expertise Despite being established relatively recently, Relief Power Control Panel has built its reputation on a foundation of quality craftsmanship and technical excellence. The company employs a skilled team that understands the intricacies of electrical panel design and manufacturing, ensuring that each product meets stringent performance standards. Their commitment to using premium materials and industry-accepted designs results in MCC panels that deliver consistent reliability in demanding industrial environments.

- Customisation Capabilities Recognising that different facilities have unique operational requirements, Relief Power Control Panel emphasises tailored solutions that align with specific client needs. Whether you require specific starter configurations, particular IP ratings for environmental protection, or specialised control voltage facilities with control transformers, their team can develop customised MCC panels that perfectly match your operational parameters.

- Comprehensive Service Approach Beyond manufacturing, Relief Power Control Panel provides complete solutions that include professional installation services. This end-to-end service model ensures proper integration of MCC panels into your existing electrical systems, maximising their performance and longevity. Their expertise extends to electric cable tray installation, creating cohesive electrical infrastructures that support efficient operations.

- Focus on Safety and Compliance. Safety remains paramount in industrial electrical systems, and Relief Power Control Panel designs its MCC panels with integrated protection features that mitigate risks of overloads, short circuits, and other electrical faults. Their products are developed with adherence to relevant industry standards, though specific certifications would need to be confirmed directly with the company as they continue to establish their compliance portfolio.

- Deep Industry Expertise and Customisation: Relief Power doesn’t believe in one-size-fits-all solutions. Their team works closely with clients to understand unique load profiles, environmental challenges like high temperatures or dust and future expansion plans. This collaborative approach results in a panel that is not just a product, but a custom-engineered solution for your specific operational reality.

- Cost-Effectiveness & Scalability: While an initial investment, a well-built MCC panel saves money in the long run. It reduces installation wiring costs, minimizes unplanned downtime, and lowers energy bills. Furthermore, its scalable architecture means new motor controls can be added seamlessly as your Gujarat-based business grows, protecting your investment for the future.

- Enhanced Safety & Protection: A primary function of an MCC is to protect both personnel and expensive equipment. It integrates advanced protection mechanisms like overload relays, short-circuit protection, and earth fault relays. By centralizing control, it minimizes the risk of electrical accidents and contains faults before they cause catastrophic damage or fire.

- Maximized Operational Efficiency: Centralized control simplifies the operation and monitoring of numerous motors from a single location. This leads to quicker response times, more efficient processes, and significant energy savings. Modern MCCs can incorporate Variable Frequency Drives (VFDs) and soft starters, which optimize motor speed and reduce power consumption.

Applications of Motor Control Centre Panels

1. Manufacturing Plants

- MCC panels manage multiple machines in manufacturing units, from conveyor belts to robotic systems. With centralised control, factory managers can monitor motor performance, reduce manual intervention, and maintain a smooth production flow.

2. Water Treatment and Pumping Stations

- In Gujarat, water supply and wastewater management are critical. MCC panels control pump operations, ensuring efficient water distribution and maintaining pressure levels across various pipelines.

3. HVAC Systems

- Large commercial buildings and industrial facilities rely on heating, ventilation, and air-conditioning systems. MCC panels regulate multiple motors in HVAC systems, ensuring consistent climate control and energy efficiency.

4. Power Plants and Substations

- MCC panels play a vital role in power generation and distribution. They control and protect generators, transformers, and auxiliary motors, ensuring an uninterrupted electricity supply.

5. Chemical and Pharmaceutical Industries

- These industries require precise control over process pumps, mixers, and agitators. MCC panels provide accurate motor control to maintain consistent product quality and safety standards.

6. Textile and Fabrication Units

- In textile industries, MCC panels manage spinning machines, looms, and finishing equipment. Centralised control improves efficiency, reduces energy consumption, and simplifies maintenance.

7. Automotive and Heavy Machinery Industries

- Gujarat’s automotive and heavy machinery sector utilises MCC panels to manage multiple production lines. From assembly units to robotic systems, these panels provide reliable control and monitoring, enhancing productivity and safety.

8. Pharmaceutical Industry

- Precision is key in pharmaceuticals. MCC panels ensure smooth operation of mixers, filling machines, and HVAC systems, maintaining the quality and hygiene standards required.

9 Food and Beverage Industry

- MCC panels control motors used in packaging, processing, refrigeration, and material handling, ensuring uninterrupted production and compliance with safety standards.

Table of Specifications Motor Control Centre Panel

| Specification | Details |

|---|---|

| Material | Motor Control Centre Panel |

| Rated Voltage | 415V AC, 3 Phase, 50Hz |

| Rated Current | Up to 4000A (customizable) |

| Protection | MCCB / ELCB / Overload Relay |

| Control Supply | 230V AC / 24V DC |

| Enclosure Material | CRCA Steel / Stainless Steel |

| Surface Finish | Powder Coated / Epoxy Coated |

| Mounting | Floor / Wall Mounted |

| Number of Motor Starters | 4 to 24 (customizable) |

| Communication Protocol | Modbus / Profibus / Ethernet (optional) |

| Operating Temperature | -10°C to 50°C |

| IP Rating | IP42 / IP54 / IP55 (as per requirement) |

| Standard Compliance | IEC 61439 / IS 8623 / UL 508A |

Benefits of Motor Control Centre Panel

- Enhanced Safety: By centralising control of potentially hazardous electrical equipment, MCCs significantly reduce operator exposure to live components. Properly designed MCCs with secure enclosures prevent accidental contact with energised parts, while clearly labelled disconnects ensure safe lockout/tagout procedures during maintenance. In Gujarat’s industrial sectors—from chemical processing in Ankleshwar to textile manufacturing in Surat—this safety-first approach protects both personnel and valuable equipment.

- Space Optimisation: Industrial floor space represents prime real estate. MCCs consolidate what would otherwise be scattered control stations into a single, organised footprint. This vertical integration is particularly valuable in Gujarat’s urban industrial areas, where facility expansion is constrained by space limitations.

- Operational Efficiency: Centralised control means operators can monitor and manage multiple motors from one location, reducing response time to issues and simplifying routine operations. With all controls logically arranged, troubleshooting becomes more intuitive, and coordinating motor sequences for complex processes becomes manageable.

- Reduced Downtime: Modular MCC design allows individual motor starter units to be quickly replaced or serviced without disrupting the entire system. This “hot-swappable” capability—where permitted by safety standards—can cut maintenance time dramatically. For Gujarat’s continuous process industries like ceramics in Morbi or pharmaceuticals in Ahmedabad, minimising downtime directly impacts the bottom line.

- Scalability and Flexibility: As production needs evolve, MCCs can be expanded by adding new sections or upgrading existing ones. This modular approach future-proofs electrical infrastructure investments, allowing Gujarat’s growing industries to adapt without completely overhauling their power distribution systems.

- Environmental Specifications: Gujarat’s diverse industrial environments—from coastal areas with higher humidity to inland regions with dust challenges—require careful consideration of IP (Ingress Protection) ratings. Standard IP55-rated panels provide solid protection against dust and water jets, but specific conditions may warrant higher specifications.

- Technical Specifications Alignment: Key parameters, including rated voltage commonly 415V in Indian industrial applications, rated current up to 2000A or higher, phase configuration typically three-phase and automation grade, should align precisely with operational requirements.

- Lifecycle Cost Analysis: While initial investment represents a consideration, the long-term benefits of MCC panels, including reduced maintenance costs, minimised downtime, and energy efficiency, typically deliver substantial return on investment over the system’s operational life.

Types of Motor Control Centre Panel

1. Standard MCC Panels

- These panels are the most common type, used for general motor control applications. Standard MCC panels include motor starters, circuit breakers, fuses, and control devices to handle motors of various ratings.

2. Customised MCC Panels

- Every industry has unique requirements. Customised MCC panels are designed and built to meet specific operational needs. Relief Power Control Panel offers bespoke solutions, ensuring compatibility with all motor types and system requirements.

3. Compact MCC Panels

- For industries with space constraints, compact MCC panels are an ideal solution. These panels provide the same functionalities as standard MCC panels but in a smaller footprint, making them suitable for modular setups.

4. Intelligent PLC-Based MCC Panels

- Modern industries are adopting automation for enhanced efficiency. Intelligent MCC panels integrate Programmable Logic Controllers (PLC) and SCADA systems to provide real-time monitoring, remote operation, and predictive maintenance features.

5. Variable Frequency Drive MCC Panels

- For industries requiring variable motor speeds, VFD MCC panels are the perfect solution. They allow precise control over motor speed and torque, leading to energy savings and optimised performance.

Conclusion

Investing in a Motor Control Center Panel is crucial for Gujarati industries to achieve dependable, secure, and effective operations. Relief Power Control Panel provides superior MCC solutions that integrate cutting-edge technology, sturdy construction, and adaptable features to satisfy a range of industrial requirements. Their MCC panels offer centralized motor control, increased safety, and greater operational efficiency in manufacturing facilities and power plants. We are the best Motor Control Centre Panel Supplier in Vadodara

Purchasing a top-notch Motor Control Center Panel is essential for Gujarati enterprises striving for operational excellence, safety, and energy efficiency. Offering sturdy, dependable, and cutting-edge MCC panels suited to a variety of industrial requirements, Relief Power Control Panel distinguishes itself as a leading supplier. Relief Power Control Panel guarantees that your electrical systems are safe and optimized for optimal performance with a dedication to innovation, quality, and customer satisfaction.