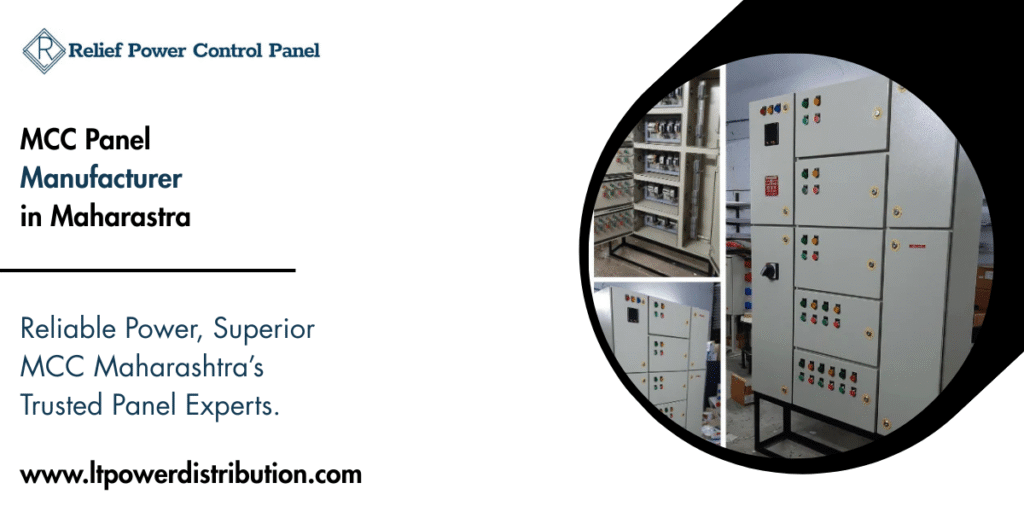

MCC Panel Manufacturer in Maharashtra

Introduction

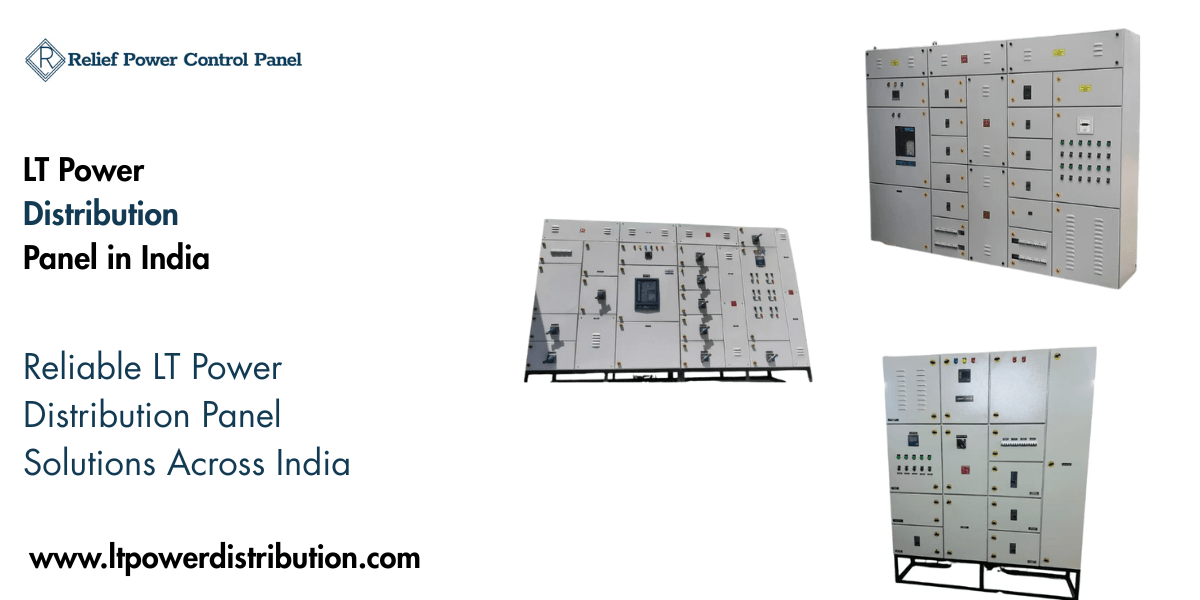

Founded in 2023 in Ahmedabad, Gujarat, Relief Power Control Panel has emerged as a trusted provider of advanced electrical control solutions. As a manufacturer, supplier, and service provider, the company specialises in high-performance systems, including power distribution panels, MCB panels, three-phase control panels, APFC panels, and VFD panels. Each product is engineered using industry-approved designs and premium-grade materials to ensure maximum safety, efficiency, and long-term reliability. Backed by a skilled team and a commitment to innovation, Relief Power Control Panel continues to establish itself as a dependable partner for power management solutions across diverse industries.

Reliable electrical distribution systems are the foundation of any facility in the fast-paced industrial environment of today. Among these systems, Motor Control Centres (MCC Panels) are essential for effectively regulating and controlling electric motors. Relief Power Control Panel provides excellent, long-lasting, and reasonably priced solutions to satisfy your industrial needs if you’re looking for a reliable MCC Panel Manufacturer in Maharashtra. We are the best MCC Panel Manufacturer in Gujarat.

Effective power distribution and regulation are more important than ever in Maharashtra’s quickly changing industrial landscape. To guarantee smooth operations, manufacturing facilities, commercial buildings, and industries depend on reliable electrical systems. MCC panels are useful in this situation. Relief Power Control Panel, a top MCC panel manufacturer in Maharashtra, provides dependable, high-quality, and tailored solutions to satisfy the various needs of its customers.

What is an MCC Panel

An assembly of one or more enclosed sections with a common power bus and primarily motor control units is called a Motor Control Centre (MCC) Panel. These panels are made to operate multiple electric motors from one central point. Manufacturing, water treatment, HVAC systems, chemical facilities, and many other industries use MCC Panels extensively. MCC Panels guarantee continuous industrial operations by offering a strong framework to control electric motors, lowering operational hazards and downtime. We are the best MCC Panel Manufacturer in Ahmedabad.

Why Choose Relief Power Control Panel

- Unmatched Engineering Depth & Customisation Large-scale projects have complex requirements. A manufacturer of scales possesses a dedicated team of engineers with experience across diverse sectors—from chemical plants in Tarapur to textile mills in Ichalkaranji. This depth allows for sophisticated customisation. Need seamless integration with a Plant SCADA system? Require complex interlocks and PLC-based automation for an entire production line. A large manufacturer like Relief Power has the in-house expertise to design and execute these solutions, turning a standard panel into an intelligent control centre tailored for your unique process.

- Rigorous Quality Assurance & Compliance. In electrical systems, there is no room for compromise. Large manufacturers operate with certified Quality Management Systems. Their processes are documented, and their panels are built to comply with stringent international standards and Indian regulations. Every component is sourced through verified channels, and every connection is torqued to specification. This institutionalised commitment to quality mitigates risk, ensures personnel safety, and protects your expensive connected machinery from faults.

- Scalability, Reliability, and On-Time Delivery When you’re managing a large industrial project in Pune, Nagpur, or Aurangabad, timelines are critical. A large manufacturer has the production capacity, supply chain relationships, and project management bandwidth to handle big orders and deliver them on schedule. They are equipped to scale up production to meet your deadlines without sacrificing quality, a challenge smaller units often face. This reliability in delivery keeps your project on track.

- Future-Proofing and Technological Edge: The industrial world is moving towards Industry Large manufacturers invest in and stay abreast of technological advancements. Whether it’s incorporating IoT-enabled devices for predictive maintenance, energy monitoring systems, or the latest safety features like arc-flash mitigation, a partner like Relief Power can future-proof your investment. They help you build not just for today’s needs, but for tomorrow’s efficiencies.

- Commitment to Customisation: Every industry has unique operational flows and challenges. A one-size-fits-all approach rarely works for critical control systems. Leading manufacturers understand the importance of flexibility and customisation. Relief Power Control Panel’s foundational approach to creating tailored solutions—whether integrating specific starters like DOL or Star-Delta, adding Variable Frequency Drives (VFDs), or designing for particular space constraints—ensures the final product aligns perfectly with your operational blueprint.

- Focus on Quality and Durability: The longevity and failure-proof operation of an MCC panel depend heavily on the quality of its components and construction. When evaluating a manufacturer, it’s crucial to consider the standards of the materials and parts used. Relief Power Control Panel manufactures panels with a focus on robust durability. For instance, their use of MS (Mild Steel) material and standardised busbars in their PCC panels points to a build designed to withstand the rigours of an industrial environment. This focus on sturdy construction translates to lower long-term maintenance costs and reliable performance.

- Comprehensive Technical Expertise: An MCC panel is a complex integration of electrical, electronic, and sometimes digital components. The manufacturer’s ability to harmonise these elements is paramount. Relief Power Control Panel’s product range, which spans from MCC and PCC panels to specialised Automatic Transfer Switch (ATS) panels, demonstrates a broad understanding of power control and distribution systems. This expertise is vital for designing a panel that not only controls motors but also interfaces seamlessly with your facility’s broader power management infrastructure.

- Clear Value Proposition: While cost is always a consideration, the cheapest option can be the most expensive in the long run due to failures and downtime. The key is to assess the overall value. Relief Power Control Panel positions its offerings to deliver “unmatched reliability and efficiency at a competitive market price. This balance between cost, performance, and the aforementioned durability offers a compelling value proposition for businesses looking to invest wisely in their operational infrastructure.

Applications of MCC Panels

1. Industrial Manufacturing Plants

- From automotive and textiles to chemicals and food processing, MCC panels are widely used in manufacturing plants to control multiple motors simultaneously. They help automate production lines, maintain operational efficiency, and ensure worker safety.

2. Water & Wastewater Treatment Plants

- In water treatment facilities, MCC panels control pumps, blowers, and other critical equipment. Their role is vital in ensuring continuous operations, proper water treatment, and efficient energy management.

3. Power Generation & Distribution

- Power plants rely on MCC panels to manage auxiliary motors and equipment. They ensure an uninterrupted power supply, regulate motor loads, and protect electrical systems from faults.

4. HVAC Systems in Commercial Complexes

- Modern commercial complexes use MCC panels to control large HVAC systems, elevators, and other motor-driven systems. This ensures smooth operation, energy efficiency, and reliable building management.

5. Oil, Gas & Petrochemical Industries

- MCC panels are essential in hazardous industries like oil and gas, where motors control pumps, compressors, and other equipment. The panels provide safe and reliable motor control even under challenging conditions.

6. Renewable Energy Projects

- Solar and wind power projects use MCC panels to manage auxiliary motors, inverters, and other motor-driven systems. MCC panels contribute to efficient energy distribution and equipment protection in renewable energy setups.

7. Chemical and Petrochemical Industries

- Chemical plants require precise motor control for mixers, agitators, pumps, and other critical equipment. MCC panels ensure that operations run smoothly, preventing equipment failure and maintaining process safety.

8. Renewable Energy Installations

- With the growing emphasis on renewable energy, MCC panels are increasingly used in solar and wind power plants. They manage motorised systems, inverters, and auxiliary machinery, ensuring optimised energy utilisation.

Table of Specifications MCC Panel

| Specification | Details |

|---|---|

| Material | MCC Panel |

| Frequency | 50 Hz |

| Phases | 3 Phase |

| Protection | MCB, MCCB, Overload Relays |

| Rated Voltage | 415V AC |

| Finish | Powder Coated / Epoxy Painted |

| Ingress Protection | IP 42 / IP 54 (Optional) |

| Busbar Material | Copper / Aluminum |

| Control Type | Star-Delta, Soft Starter, VFD Integration |

| Mounting | Floor Mounted / Wall Mounted |

| Customization | Copper / Aluminium |

| Standards | IEC, IS, and Other Industrial Standards |

Benefits of MCC Panel

- Enhanced Operational Safety & Protection. Safety is paramount. MCC panels are engineered with multiple layers of protection. They guard motors against critical faults like overcurrent, overload, phase failure, and short circuits, preventing catastrophic equipment damage and fire hazards. Features like emergency shutdown protocols and secure, compartmentalised construction ensure personnel safety during both normal operation and maintenance activities.

- Maximised Uptime & Reduced Downtime. Unplanned downtime is a major cost driver. MCC panels facilitate centralized administration and rapid operations, making it easier for your team to monitor and control the entire system. Their modular design, especially in draw-out type units, allows for quick removal and replacement of faulty components without shutting down the entire production line, minimising operational interruptions.

- Significant Space & Cost Efficiency. By integrating the controls for numerous motors into a single, vertical assembly, MCC panels save valuable factory floor space. This consolidated approach also translates to cost savings in installation, wiring, and long-term maintenance compared to managing dozens of individual starters scattered across the facility.

- Customised Engineering Solutions: Off-the-shelf panels rarely fit perfectly. Local manufacturers excel at providing custom design services. They can tailor the MCC’s specifications—from busbar material, copper or aluminium and IP protection rating for dust and water resistance. to the integration of specific starters like Variable Frequency Drives to match your exact process requirements.

- Enhanced Safety & Protection: Safety is paramount. MCC panels integrate critical protective devices such as overload relays and circuit breakers that guard motors against faults like overcurrent, phase failure, and short circuits. This not only prevents costly motor burnouts but also mitigates risks to personnel. Advanced features like emergency shutdown capabilities provide an added layer of control during critical situations.

- Maximised Operational Efficiency & Uptime: Downtime is expensive. MCC panels facilitate centralised control and monitoring, allowing for rapid response to operational needs and quicker identification of faulty components. Their modular design, especially in draw-out or plug-in types, allows individual motor starter units to be maintained, replaced, or upgraded without shutting down the entire system, drastically reducing maintenance-related downtime.

- Significant Space Savings & Simplified Installation: Consolidating numerous individual motor starters into one organised, free-standing assembly saves valuable factory floor space. Furthermore, receiving a factory-assembled and tested MCC panel, as opposed to field-wiring dozens of separate components, simplifies installation, ensures consistency, and accelerates commissioning time.

- Inherent Scalability for Future Growth: Industrial needs evolve. A well-designed MCC is built with expansion in mind. Its structure allows for the seamless addition of new sections and units as you add more equipment or processes to your facility. This forward-thinking design protects your initial investment and accommodates future growth without requiring a completely new system.

Types of MCC Panels

1. Standard MCC Panels

- Standard MCC panels are designed for typical motor control applications. They include a common busbar system, starter units, and protective devices. These panels are ideal for industries with moderate motor loads and standard operational requirements.

2. Customised MCC Panels

- Every industry has unique power distribution requirements. Customised MCC panels are designed to meet specific operational needs, including motor sizes, voltage ratings, and control systems. Our experts at Relief Power Control Panel work closely with clients to deliver fully tailored solutions.

3. PLC-Based MCC Panels

- PLC-based MCC panels integrate Programmable Logic Controllers for enhanced automation and intelligent control. These panels are suitable for industries aiming for smart operations, where precise motor control, sequencing, and monitoring are essential.

4. VFD Variable Frequency Drive MCC Panels

- VFD MCC panels are designed to control the speed of motors, optimising performance and energy consumption. Industries like HVAC, water treatment, and chemical plants benefit significantly from VFD panels.

5. Indoor and Outdoor MCC Panels

- Depending on the installation environment, MCC panels can be manufactured for indoor or outdoor use. Outdoor panels are weatherproof, dustproof, and corrosion-resistant, making them suitable for exposed industrial locations.

Conclusion

Relief Power Control Panel is the best option for Maharashtra’s companies searching for dependable, long-lasting, and effective MCC panels. They provide smooth motor control, improved operational efficiency, and long-lasting performance with an emphasis on quality, cutting-edge technology, and tailored solutions.

Selecting Relief Power Control Panel as your Maharashtra MCC Panel Manufacturer ensures not only excellent products but also professional advice, prompt delivery, and thorough post-purchase assistance. Their MCC panels are made to satisfy a variety of industrial needs while guaranteeing productivity, efficiency, and safety, regardless of the size of the production facility.